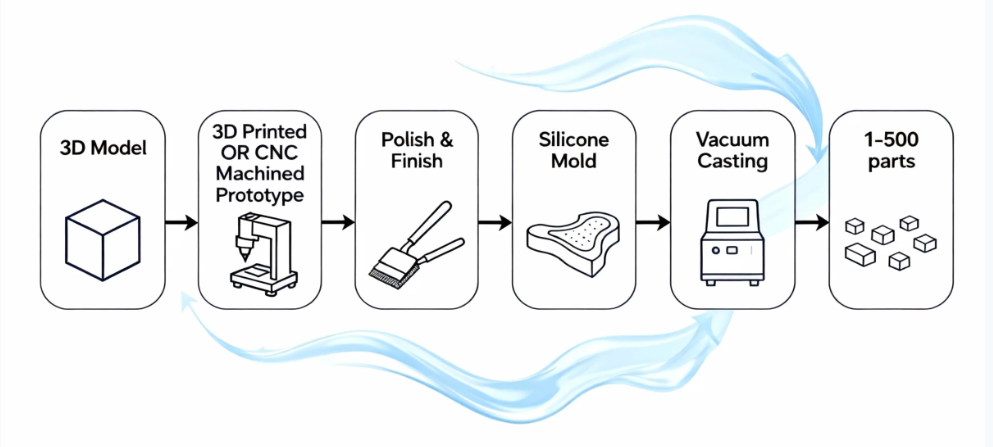

? Vacuum Casting: Rapid, High-Quality Prototypes & Small Batches

3D Model > 3D Printed OR CNC Machined Prototype > Polish & Finish > Silicone Mold > Vacuum Casting > 1-500parts

Bridge the gap between prototype and production. Vacuum casting is the ideal process for creating small quantities of high-fidelity, functional prototypes or end-use parts. It replicates the look, feel, and material properties of injection-molded parts without the high cost and lead time of a production mold.

Why Choose Vacuum Casting?

- Speed & Cost for Low Volumes: Produce 10-50 parts in days, not months, at a fraction of the cost of injection molding tooling.

- Exceptional Detail & Surface Finish: Silicone molds capture ultra-fine details and textures, yielding parts with an injection-molding-like finish right out of the cast.

- Wide Material Selection: Cast parts in a vast range of polyurethane resins that simulate the properties of ABS, PP, PC, flexible rubber, and even transparent materials.

- Ideal for Design Validation: Perfect for functional testing, market testing, pre-production assemblies, and creating presentation-quality models.

Explore how vacuum casting can accelerate your product development cycle.

? Vacuum Casting Knowledge Hub

? 1 ?? Fundamentals & When to Use It

Understand the vacuum casting process and identify the projects where it delivers the most value.

- What is Vacuum Casting? Process Overview and Advantages

- Vacuum Casting vs. Injection Molding vs. 3D Printing: A Comparative Guide

- Ideal Applications for Vacuum Casting: From Prototypes to Bridge Production

- Understanding the Cost Structure: Mold Cost, Unit Cost, and Lead Times

? 2 ?? Design for Vacuum Casting

Optimize your part design to achieve the best results from the silicone mold and casting process.

- Key Design Considerations for Vacuum Casting (Draft, Wall Thickness, Undercuts)

- How to Design Effective Molding Partitions and Air Vents

- Incorporating Inserts and Overmolding in Vacuum Casting

? 3 ?? Materials (Castable Urethanes)

Select from a wide range of castable resins to match the properties of your target production material.

- Guide to Vacuum Casting Resins: Simulating ABS, PP, PC, Rubber, and More

- Choosing Resins for Transparency, High Temperature, or Flexibility

- Material Properties: Comparing Shore Hardness, Strength, and Color Options

? 4 ?? The Process: Molding & Casting

Dive into the step-by-step workflow, from master pattern to final de-molding.

- The Vacuum Casting Workflow: A Step-by-Step Visual Guide

- Silicone Mold Making: Life, Detail Reproduction, and Maintenance

- The Casting Process: Mixing, Degassing, Pouring, and Curing

? 5 ? Post-Processing & Finishing

Explore how to finish vacuum cast parts to achieve a production-ready appearance.

- Post-Casting Operations: De-gating, Sanding, and Polishing

- Painting, Metallization, and Soft-Touch Coating for Vacuum Cast Parts

- Achieving Textured and High-Gloss Finishes

? 6 ?? Applications & Case Studies

Discover how vacuum casting is used across industries for rapid prototyping and low-volume production.

- Consumer Electronics: Functional Housings and Button Prototypes

- Automotive: Interior Trim Prototypes and Fluid-Resistant Components

- Medical Devices: Ergonomic Models and Compliance Testing Prototypes

? 7 ?? Quality & Technical Limits

Understand the capabilities, tolerances, and best practices to ensure part quality.

- Achievable Tolerances and Dimensional Accuracy in Vacuum Casting

- Common Defects in Vacuum Casting (Air Bubbles, Incomplete Fills) and Solutions

- Best Practices for Master Pattern Preparation and Mold Design